Aluminum Alloy DieCasting Process Case

2023-08-18 10:30

Weight of casting:1.4 kg(including 0.6 kg of inserts).

Wall thickness:2~2.5mm.

Projection area:150mm square

1. technical requirements

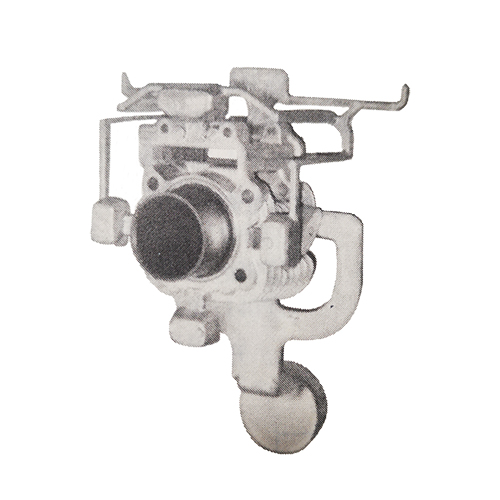

1) Pressure resistance. The casting structure is shown in Figure 18-23.

2) Material: ADC12.

3) Die-casting machine: 500t.

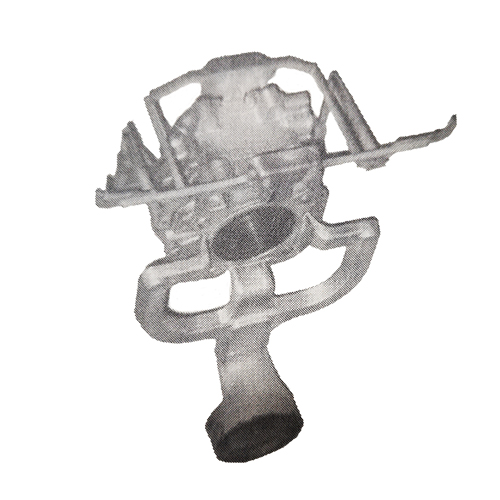

4)Pouring system design: to establish good filling conditions and sufficient exhaust, see Figure 18-24.

5)Adopt the casting method, and set wear-resistant cast iron cylinder liner.

Figure 18-23 Die casting with cast iron cylinder liner Figure 18-24 Forms of pouring system and overflow system

2. Die casting process parameters

1) low speed: 0.3 m/s.

High-speed speed: 3 m/s.

2) low-speed stroke: 310 mm.

High-speed start point:310mm.

High-speed travel:130mmo

3)Accumulator pressure:10 MPa.

Booster pressure:20 MPa.

Specific pressure of injection:75 MPao

4)Holding time:10 s.

5)Punch diameter:p70mm.

Pouring metal quantity: 2 kg

Shank thickness: 25 mm

6)Pouring temperature:660C

7)Mold release agent: water-based paint

8)punch lubricant: oil-based (graphite-free), in order to maintain the surface of the casting is bright and clean

3. Die casting process

Cleaning the cavity and spraying → Installation of inserts → Insertion of movable mold core 1 → Insertion of movable mold core 2 → Insertion of movable mold core 3 → Insertion of movable mold core 4 → Closing of the mold → Pouring → Injection → Opening of the mold → Withdrawal of the core 4 → Withdrawal of the core 3 → Withdrawal of the core 2 → Withdrawal of the core 1 → Ejecting of castings → Removal of the castings → Cutting of edges

Get the latest price? We will reply as soon as possible (within 12 hours)