Introduction and Application of Die Casting Process(Part 2)

2023-12-29 09:58

Application Areas:

Die-casting, an efficient non-cutting metal rapid forming method, has been widely used in various industries worldwide, including aviation, aerospace, weapons, ships, automobiles, motorcycles, bicycles, instruments, industrial electrical appliances, household appliances, lamps, toys, agricultural machinery, daily necessities and instruments, clocks, cameras, camcorders, computers, textile machinery, construction and civil hardware, telecommunications, etc. The manufacturing industry, especially in toys, vehicles, instruments, and laptop production, is its primary application area, with automobiles accounting for approximately 70% and motorcycles about 10%. Currently produced die-castings range from the smallest at 3-5g (such as zipper joints) to the largest aluminum alloy die-casting weighing over 50kg, with a maximum diameter of 2.5-3m, presenting various shapes and structures.

1. Simplified Types: Such as pipes, covers, instrument covers, camera covers, etc.

Professional digital camera housing

2. Circular Cover Types: Such as various covers, machine covers, notebook computer chassis, zinc alloy jewelry box covers, tea box covers, etc.

Engine cylinder head

3. Circular Disk Types: Such as number plate bases, instrument panels, food trays, etc.

Instrument board

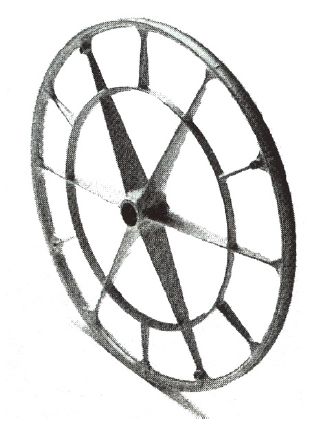

4. Circular Ring Types: Such as steering wheels, connector rings, bicycle and sports equipment rims, car rims, climbing rings, etc.

spoke

5. Framework Types: Such as mobile phone frames, car door frames, various instrument and instrument frames, magnesium alloy car body frames, fishing reel frames, etc.

Fishing line wheel holder

6. Cover Types: Such as anti-tank rocket propellant covers, machine wheel covers, etc.

Differential housing

7. Shell Types: Such as car and motorcycle cylinder oil pump shells, NB machine shells for 3C products, mobile phone shells, digital camera shells, liquid crystal projector shells, PDA shells, LCD-TV shells, PDP-TV shells, digital camera shells, disc player shells, motor shells, etc.

Radio housing

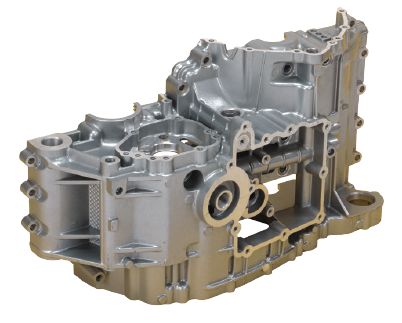

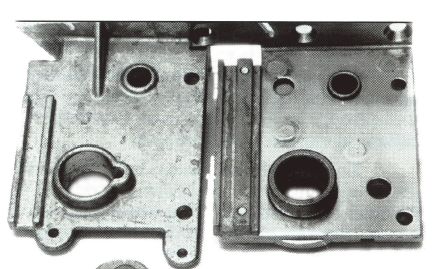

8. Porous Cylinder Blocks: Such as automobile and motorcycle cylinder blocks, etc.

Motorcycle down crankcase

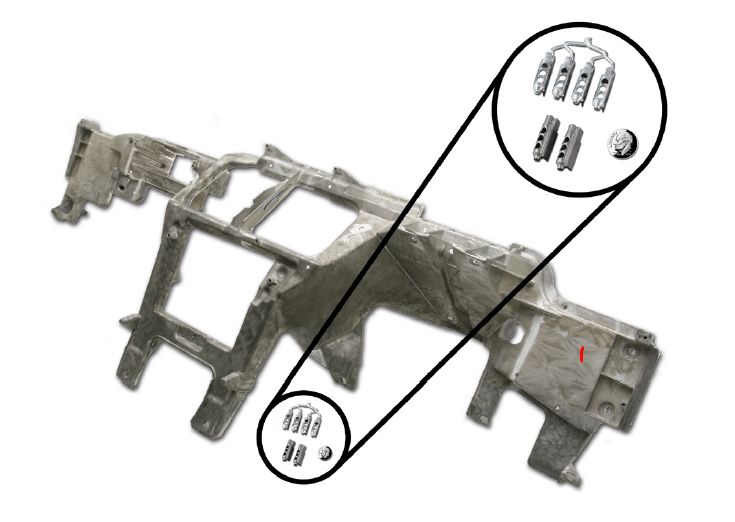

9. Chassis Types: Such as car and snowmobile chassis, etc.

Rearview mirror and sensor mount

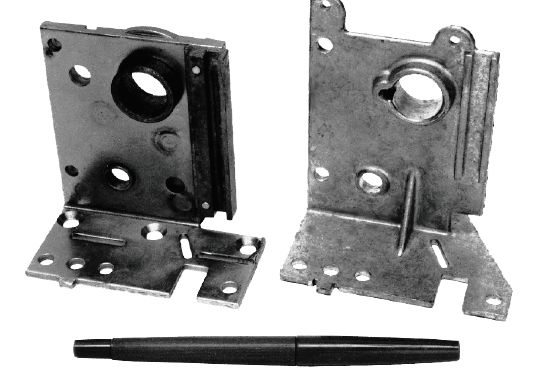

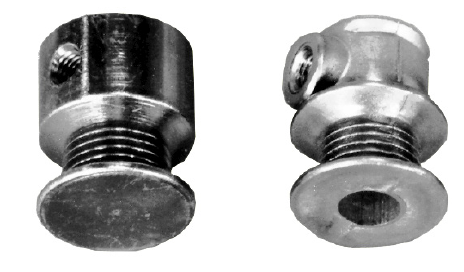

10. Bracket Base Types: Such as car suspension brackets, aircraft oxygen supply device brackets, baby care box heating element stators, sleds, luggage racks, frames, ice skate brackets, suitcase brackets, car front frames, headlight brackets, front brackets, etc.

Bearing bracket

11. Plate Types: Such as brake pedals, instrument panels, suspension chassis, electronic heat sinks, etc.

12. Irregular Complex Types: Such as air-to-air missile wings, tail cones, beams, video channel converters, booster rotors, car driver seats, pilot seat frames, Airbus oxygen mask brackets, decorative die-castings composed of ribbons, etc.

Get the latest price? We will reply as soon as possible (within 12 hours)