Introduction to Die Casting Process

2023-11-29 05:47

With the swift advancement of metal die-casting technology, Tesla has pioneered the integration of die-cast bodies, consolidating 70 components into a single die-casting process (now reduced to 2, eventually to 1). Many automakers have followed suit, as integrated die-casting technology possesses unique charm. So, what is metal die-casting technology? Let's provide a brief overview today.

What is Die-Casting?

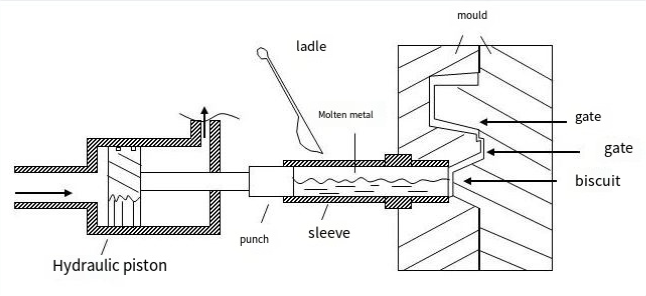

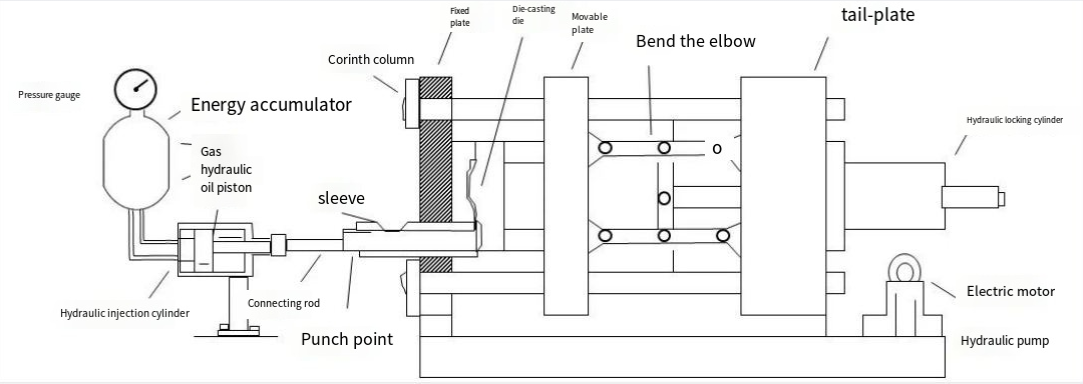

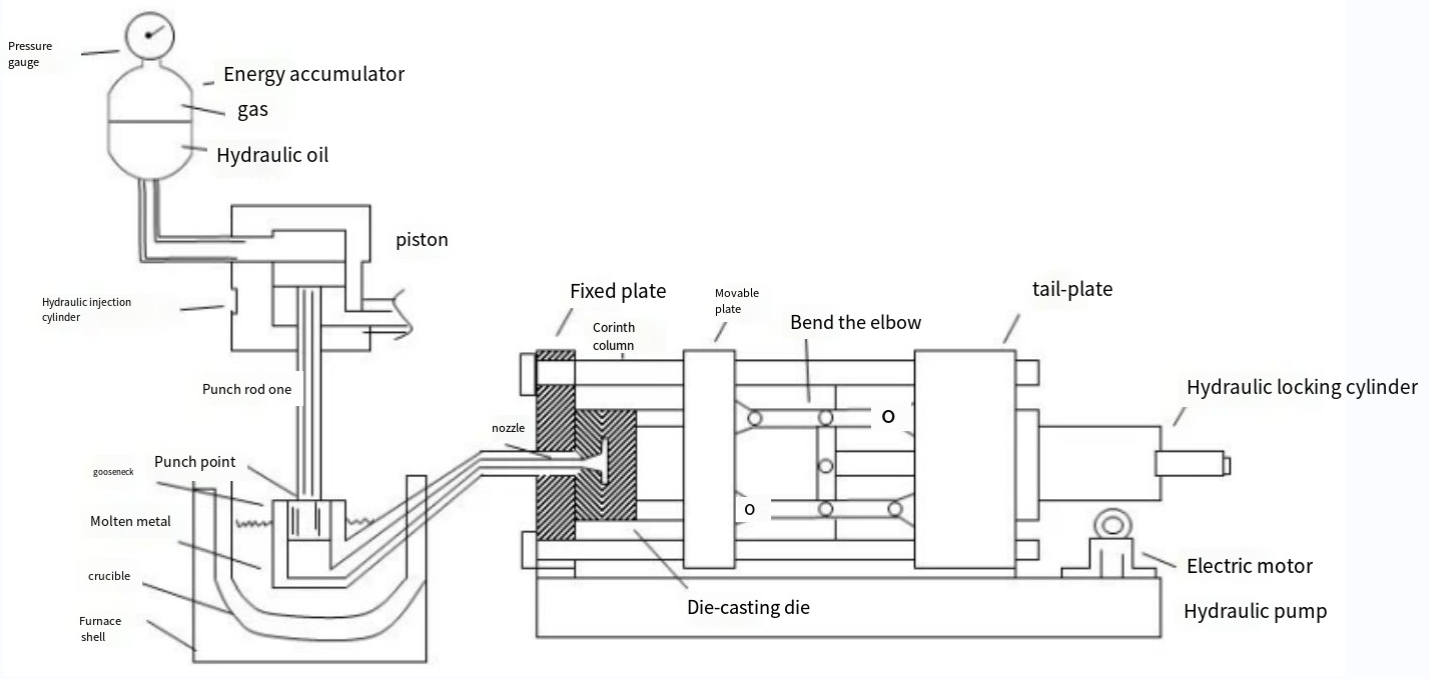

Die-casting is a non-cutting, specialized casting method in modern metal processing. It involves using machines, molds, and alloys to uniformly control pressure, speed, and time. This process fills the mold with molten metal at high pressure and speed, crystallizing and solidifying it into a casting.

Die-casting equipment converts electrical energy into hydraulic energy through a motor, driving actions like opening and closing molds and injecting molten metal into mold cavities.

Die casting process flow chart

Advantages and Disadvantages of Die-Casting:

Advantages:

Manufactures complex, well-defined, thin-walled metal parts.

High production efficiency.

High material utilization; minimal post-processing required for final product shape.

Disadvantages:

Common presence of pores and oxide inclusions in die-castings.

Size limitations and restricted alloy types.

Key Die-Casting Alloys:

The selection of die-casting alloys is crucial, considering performance, processability, application, and production conditions.

Al Alloy: Aluminum alloys offer excellent flowability, shaping versatility, precise dimensions, good casting performance, low density, high strength, corrosion resistance, wear resistance, thermal conductivity, and electrical conductivity.

AL-Zn Alloy: After natural aging, die-castings achieve higher mechanical performance.

Die-Casting Equipment and Manufacturers:

The choice of die-casting machines significantly influences product quality, production efficiency, and management costs. Properly selecting suitable die-casting machines is a technically and economically crucial task.

Types of Die-Casting Machines:

Hot Chamber Die-Casting Machine: Zinc alloy, magnesium alloy, etc.

Cold Chamber Die-Casting Machine: Zinc alloy, magnesium alloy, aluminum alloy, copper alloy, etc.

Vertical Die-Casting Machine: Zinc, aluminum, copper, lead, tin.

The difference between hot chamber and cold chamber lies in whether the shot system of the die-casting machine is immersed in the metal solution. Die-casting machines can also be classified as horizontal and vertical.

Cold chamber die casting machine structure

Hot chamber die casting machine structure

Current Applications of Die-Casting Technology:

Due to its high production efficiency, complexity, precision, and versatility, die-casting technology finds widespread use in the automotive, tractor, electrical instrument, telecommunications equipment, aerospace, medical equipment, and light industrial hardware industries. Key die-cast components include engine cylinder blocks, cylinder heads, gearbox housings, engine covers, instrument and camera housings, brackets, etc.

Get the latest price? We will reply as soon as possible (within 12 hours)