Mold Design for Aluminum Alloy Die-Casting Housing

2024-02-02 10:58

Die-casting is widely used in various fields such as automobiles, 3C products, and hardware parts due to its high efficiency, high material utilization, and high forming accuracy. To meet the specific die-casting requirements, corresponding die designs are necessary. For housing components, a side-gate die casting mold is used, and the design and manufacturing of this mold are crucial for ensuring the quality of aluminum alloy die-castings. Taking the example of an aluminum alloy housing, this article introduces the design of a die-casting mold for a horizontal cold chamber die-casting machine.

A detailed process analysis was conducted for a specific aluminum alloy die-casting housing. The structural design of the die-casting mold for a horizontal cold chamber die-casting machine was elaborated, covering aspects such as parting surface selection, gating system design, side-core pulling design, and mold release mechanism design. The working principles and structural features of this die-casting mold were explained, providing reference for the design of die-casting molds for horizontal cold chamber die-casting machines.

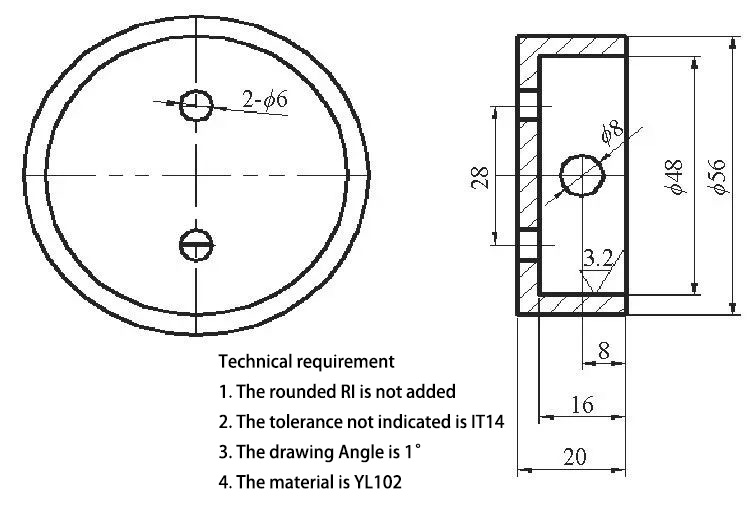

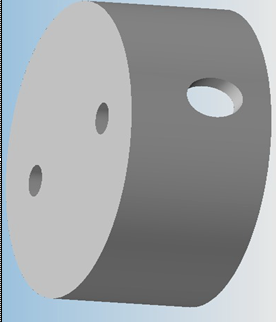

The housing structure is shown in Figures 1 and 2. The casting requires high strength, lightweight, and operates in high-temperature and high-humidity environments above 100°C. Therefore, YL102 aluminum alloy was chosen for its melting point of 650°C, and a metal crucible was used due to its high Si content. The casting has 2 φ6mm through-holes and φ8mm blind holes, with a cylindrical shape of φ56mm. The 2 φ6mm through-holes have a center distance requirement of 280-0.2mm, and the dimensional accuracy of the casting is not high. The casting has good formability, requiring a smooth surface with no casting defects such as cracks, cold shuts, or air holes. The draft angles on both the inner and outer surfaces are set at 1°, and the wall thickness of the casting is 4mm, with rounded transitions at the inner and outer cylindrical surfaces with a radius of 1mm. The die-casting process parameters are as follows: injection pressure is 65MPa, filling speed is 42m/s, pouring temperature is 630°C, mold preheating temperature is 160°C, filling time is 0.1s, and sodium fluoride water is used as a coating. The clamping force was calculated using the projected area method, and the J1110A horizontal cold chamber die-casting machine was selected, with a chamber inner diameter of φ40mm, outer diameter of φ90mm, and injection stroke of 0-120mm.

Figure 1: Housing Plan View

Figure 2: Housing 3D View

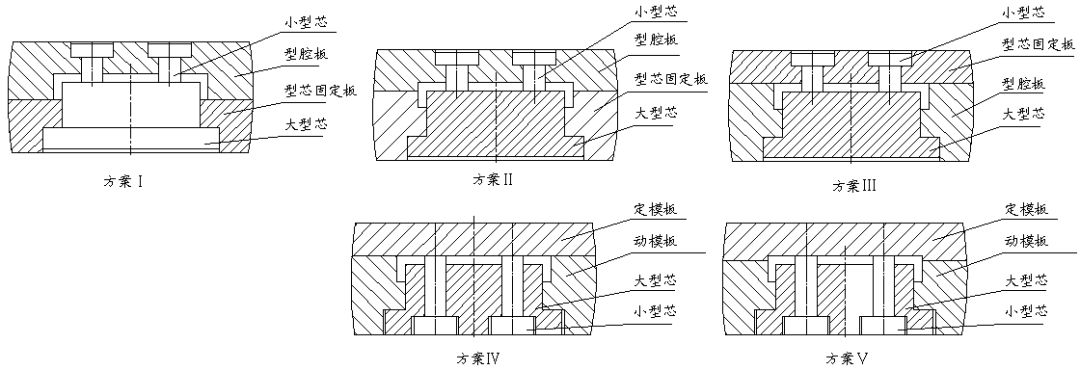

Figure 3: Housing Parting Surface Scheme

(1) Scheme I: The large core of the die-casting mold is placed in the fixed core plate, and the cavity and small core are placed in the cavity plate. The disadvantage is that the symmetry of the 2 φ6mm small holes with the centerline of the outer φ56mm and inner φ48mm holes of the casting is difficult to guarantee.

(2) Scheme II: Part of the die-casting mold cavity and the large core are placed in the core fixed plate, and the other part of the cavity and the small core are placed in the cavity plate. The disadvantage is that the symmetry of the 2 φ6mm small holes with the centerline of the outer φ56mm and inner φ48mm holes of the casting is difficult to guarantee.

(3) Scheme III: The die-casting mold cavity and the large core are placed in the cavity plate, and the small core is placed in the core fixed plate. The advantage is that the casting's flashing is not on the assembly reference surface.

(4) Scheme IV: The die-casting mold cavity and both large and small cores are all placed in the movable mold. The advantage is that the symmetry of the 2 φ6mm small holes with the centerline of the outer φ56mm and inner φ48mm holes of the casting can be ensured.

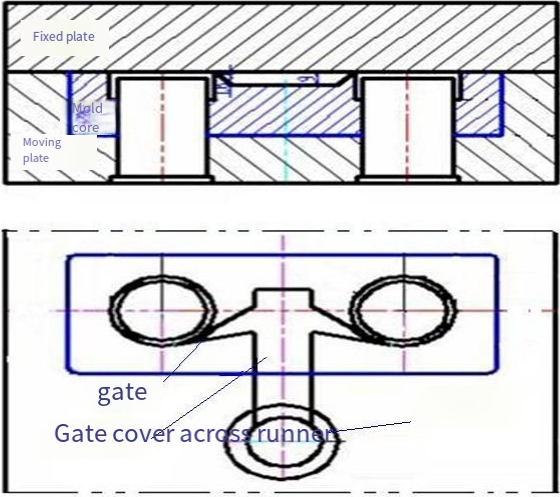

Figure 4: Housing Gating System

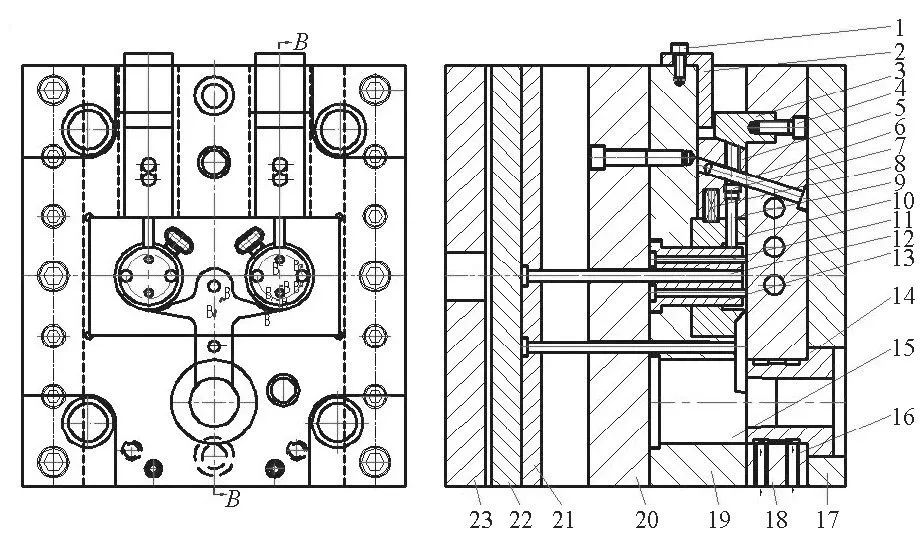

Figure 5: Housing Die-Casting Mold Assembly

1. Internal hexagon screw 2. Limiting plate 3. Wedge block 4. Ejector 5. Slider 6. Inclined guide pillar 7. Top wire 8. Spring 9. Side core 10. Moving mold core 11. Small core 12. Top rod 13. Large core 14. Sprue bushing 15. Flow cone 16. Copper tube 17. Fixed mold base plate 18. Fixed mold plate 19. Moving mold plate 20. Support plate 21. Push rod fixed plate 22. Push plate 23. Moving mold base plate

Figure 6: Die-Cast Housing Components

Get the latest price? We will reply as soon as possible (within 12 hours)