The Role and Design Principles of Reinforcement Ribs in Die-Casting Parts

2024-01-15 10:22

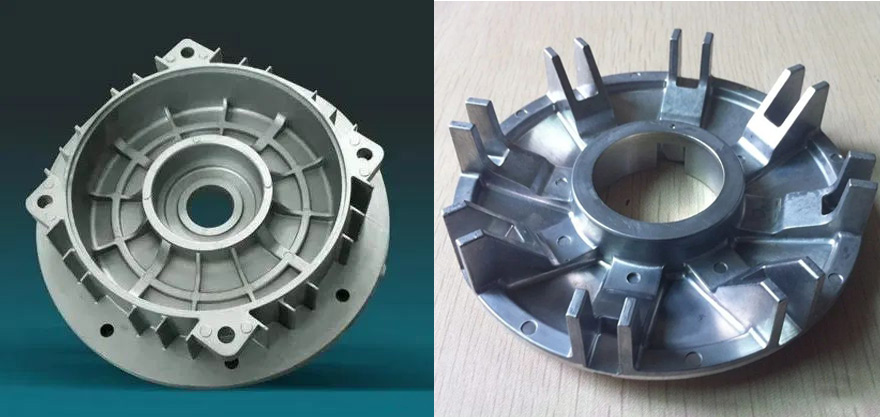

Reinforcement ribs play a crucial role in enhancing the strength and rigidity of die-casting parts. They are particularly beneficial for avoiding issues such as shrinkage, fracture, and deformation in flat or thin-walled die-casting components. The strategic addition of reinforcement ribs effectively prevents these problems, thereby strengthening the overall part and improving its mechanical properties.

1. Definition of Reinforcement Ribs:

In structural design, when faced with large overhangs or spans that exceed the load-bearing capacity of the connecting surfaces, reinforcement ribs, commonly known as strengthening ribs, are added to the common vertical face of two joint bodies. This addition increases the strength of the connecting surfaces.

2. Functions of Reinforcement Ribs in Die-Casting Parts:

Enhanced Strength and Rigidity:

Reinforcement ribs primarily serve to enhance the strength and rigidity of die-casting parts. By strategically adding an appropriate number and positioning of reinforcement ribs, it's possible to effectively increase the tensile and bending strength without increasing the wall thickness excessively.

Mitigation of Deformation Defects:

Reinforcement ribs help overcome stress non-uniformity caused by differences in wall thickness in die-casting parts, reducing the likelihood of warping and twisting defects.

Material and Cost Efficiency:

By reducing the wall thickness of die-casting parts and avoiding the need for increased thickness, reinforcement ribs contribute to minimizing porosity, saving metal, reducing weight, and lowering overall prduction costs.

Improvement of Metal Flow:

Acting as pathways for the flow of molten metal, reinforcement ribs ensure a smoother metal flow during the die-casting process. This enhances the manufacturability of parts, reducing the risk of deformation or failure during use and, consequently, increasing the lifespan and reliability of the parts.

Besides their structural functions, reinforcement ribs can assist in heat dissipation, serve decorative purposes, and contribute to the overall aesthetics of the die-cast part.

2. Design Principles for Reinforcement Ribs in Die-Casting Parts:

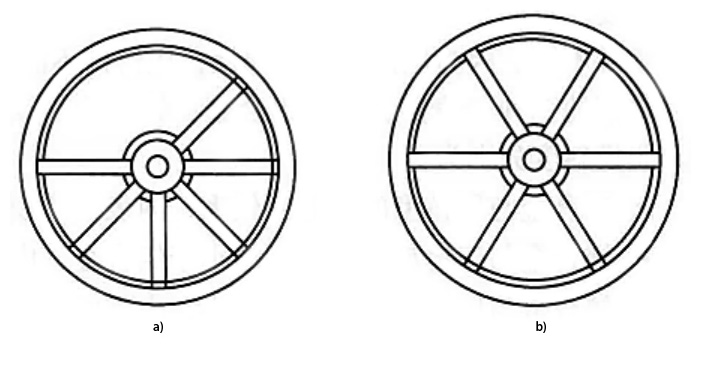

Alignment with Main Force Directions:

Reinforcement ribs should be placed along the primary force direction to improve the part's tensile and bending performance under stress.

Optimal Cross-Sectional Shape:

The cross-sectional shape of reinforcement ribs should be chosen judiciously, with options like rectangles or circles being common geometric choices.

Dimensional Requirements:

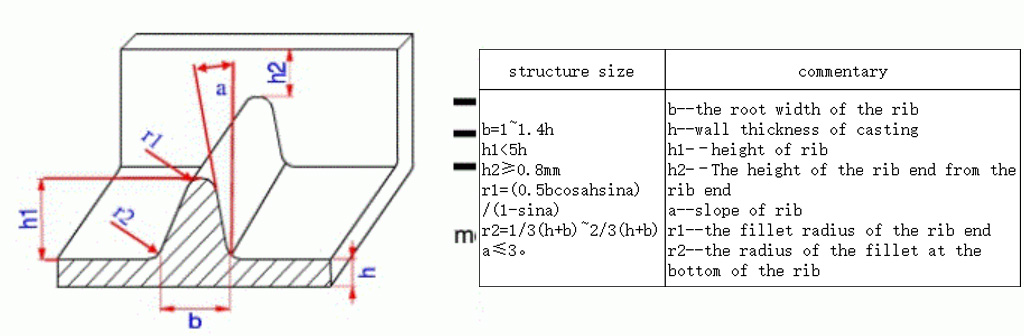

1) Thickness: Generally not exceeding 50%-80% of the wall thickness of the die-casting part.

2) Height: Typically not exceeding five times the thickness of the reinforcement rib.

Proper Placement:

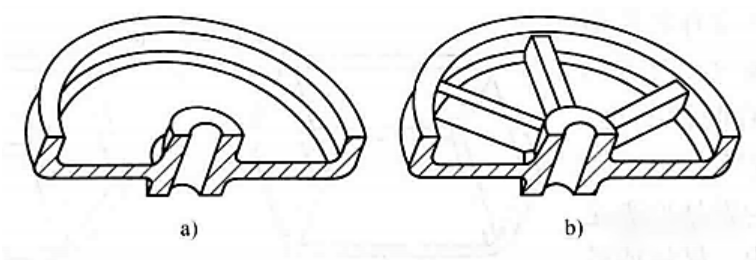

Reinforcement ribs should be symmetrically arranged, ensuring uniform wall thickness to avoid casting defects such as shrinkage holes, air pockets, or cracks.

Flow Alignment:

The flow direction of the molten metal in the reinforcement ribs should align with the overall metal flow direction in the die-casting process.

Root Considerations:Rounded corners should be added to the base of the reinforcement ribs to avoid abrupt changes in the section, aiding in metal flow and stress distribution, ultimately enhancing part strength.

By adhering to these design principles, reinforcement ribs contribute significantly to the overall performance, reliability, and cost-effectiveness of die-casting parts.

Get the latest price? We will reply as soon as possible (within 12 hours)