What Things Are Cast? Detailed Explanation of the Most Complete Casting Process in History(Part2)

2024-02-12 08:00

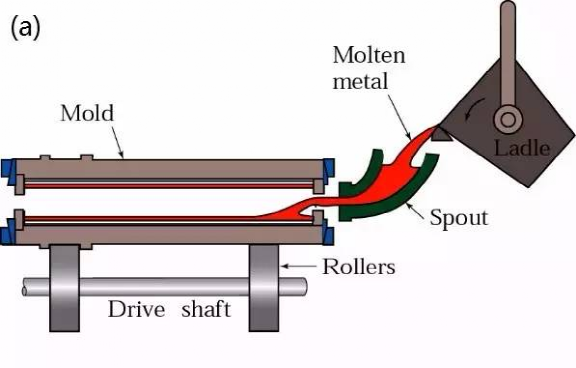

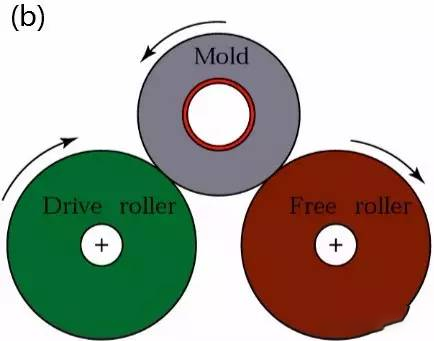

(5) Centrifugal casting

Centrifugal casting: It is a casting method that pours molten metal into a rotating mold, fills the mold under the action of centrifugal force and solidifies.

Process flow:

Process characteristics

advantage:

1. There is almost no metal consumption in the gating system and riser system, improving the process yield;

2. No core is needed when producing hollow castings, so the metal filling ability can be greatly improved when producing long tubular castings;

3. The casting has high density, few defects such as pores and slag inclusions, and high mechanical properties;

4. It is convenient to manufacture composite metal castings such as cylinders and sleeves.

shortcoming:

1. There are certain limitations when used to produce special-shaped castings;

2. The diameter of the inner hole of the casting is inaccurate, the surface of the inner hole is rough, the quality is poor, and the machining allowance is large;

3. Castings are prone to gravity segregation.

application:

Centrifugal casting was first used to produce cast pipes. Centrifugal casting technology is used in metallurgy, mining, transportation, drainage and irrigation machinery, aviation, national defense, automobile and other industries at home and abroad to produce steel, iron and non-ferrous carbon alloy castings. Among them, the production of castings such as centrifugal cast iron pipes, internal combustion engine cylinder liners and bushings is the most common.

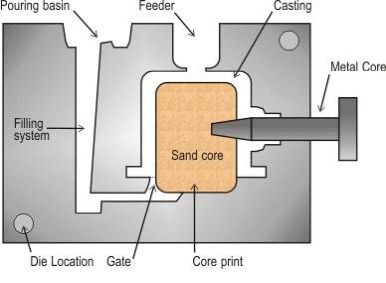

Metal mold casting: refers to a molding method in which liquid metal fills a metal mold under the action of gravity and cools and solidifies in the mold to obtain a casting.

Process flow:

Process characteristics

advantage:

1. The metal mold has large thermal conductivity and heat capacity, fast cooling rate, dense casting structure, and mechanical properties that are about 15% higher than those of sand mold castings.

2. Castings with higher dimensional accuracy and lower surface roughness values can be obtained, and the quality stability is good.

3. Because sand cores are not used or rarely used, the environment is improved, dust and harmful gases are reduced, and labor intensity is reduced.

shortcoming:

1. The metal mold itself is not breathable, and certain measures must be taken to lead out the air in the mold cavity and the gas generated by the sand core;

2. The metal mold has no concession, and cracks are prone to occur when the casting solidifies;

3. The metal type manufacturing cycle is long and the cost is high. Therefore, good economic effects can only be shown when mass production is carried out in batches.

Application:

Metal mold casting is not only suitable for mass production of complex-shaped aluminum alloy, magnesium alloy and other non-ferrous alloy castings, but also suitable for the production of iron and steel metal castings, ingots, etc.

(7) Vacuum die casting

Vacuum casting: An advanced die-casting process that eliminates or significantly reduces the pores and dissolved gases in the die-casting parts by removing the gas from the die-casting mold cavity during the die-casting process, thereby improving the mechanical properties and surface quality of the die-casting parts.

Process characteristics

advantage:

1. Eliminate or reduce the pores inside the die castings, improve the mechanical properties and surface quality of the die castings, and improve the plating performance;

2. To reduce the back pressure of the mold cavity, alloys with lower specific pressure and poor casting performance can be used, and it is possible to die-cast larger castings with small machines;

3. The filling conditions are improved and thinner castings can be die cast;

shortcoming:

1. The mold sealing structure is complex and difficult to manufacture and install, so the cost is high;

2. If the vacuum die-casting method is not properly controlled, the effect will not be very significant.

Get the latest price? We will reply as soon as possible (within 12 hours)