Analysis on the Development Prospects of China's Mold Industry

2024-02-22 08:00

Industry Development

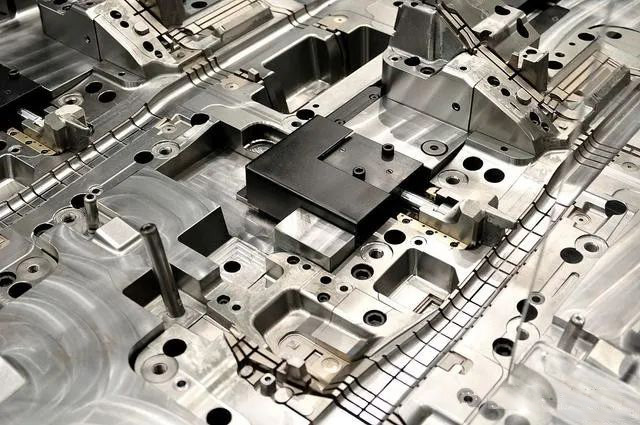

The Chinese mold industry, as a crucial component of modern manufacturing, has experienced rapid growth in recent years. With the expansion of the manufacturing industry and technological advancements, the mold industry has made significant progress in terms of scale, technological level, and application fields.

In terms of scale and quantity, the Chinese mold industry is continuously expanding. According to statistics, there are over 30,000 mold enterprises in China, with over 1 million employees, including many large-scale enterprises. This phenomenon is attributed to the increase in domestic consumption demand and the transformation and upgrading of the manufacturing industry.

In terms of technology, after years of accumulation and development, the technical level of Chinese mold enterprises has significantly improved. Many enterprises have acquired the capability for independent research and innovation, enabling them to produce high-quality and high-precision molds. This not only enhances the competitiveness of enterprises but also drives the overall technological advancement of the industry.

Molds, known as the "mother of industry," have been widely applied in various fields such as automotive, energy, and machinery. Mold technology serves as the "shaping machine" and "benefit amplifier" in the manufacturing of components for products in fields such as electronics, automobiles, appliances, instruments, household appliances, and communications. Over the past decade, the Chinese mold industry has been rapidly developing at an average annual growth rate of over 15%, which is twice the rate of China's GDP growth. With the background of China's comprehensive opening up and integration into the world manufacturing chain and economic circle, as well as the advantages of its huge demand market and reform capabilities, the Chinese mold industry has rapidly developed, steadily improved its internationalization capabilities, and has become a major player in the world mold manufacturing and consumption.

On a global scale, China has become the world's largest mold manufacturing country. In 2022, the Chinese mold market exceeded 350 billion yuan, and it is expected to reach around 380 billion yuan by 2025. The total export sales of molds in China exceed 8 billion US dollars, with molds exported to 200 countries and regions, making Chinese molds an important force on the international mold stage. Chinese molds account for about one-third of the world's mold consumption and production value, making it the most cost-effective mold manufacturing base in international mold procurement. According to the latest report from the WBA Aachen Institute of Mold Manufacturing in Germany, China is the largest market for molds, with the following rankings in terms of global competitiveness: Germany, Japan, the United States, China, South Korea, and Italy, these six major mold manufacturing countries account for the absolute market share of mold production value.

Future Prospects

With the global economic recovery and the rise of emerging markets, the mold market is expected to continue its growth trend. In addition, as the manufacturing industry continues to undergo transformation and upgrading, the mold industry will also benefit from it.

Leading Enterprises Enhance Market Share, Industry Concentration Gradually Increases

With the continuous growth of downstream applications such as automotive lightweighting, consumer electronics, and rail transportation, leading enterprises in the industry are deepening their existing customer bases, increasing research and development investment, accelerating the automation upgrade of production lines, enhancing the level of new product development, and continuously enhancing the one-stop supporting services for multi-specification and full-line products, thereby occupying the newly added market share. Meanwhile, small enterprises with low technological levels, weak technological development capabilities, and poor service capabilities will be gradually eliminated, and market resources will gradually concentrate on advantageous enterprises within the industry.

Production Manufacturing Moves towards Automation and Intelligence

With the deep application of information management technologies such as CAD/CAE/CAM integration, 3D design technology, and the development of Internet of Things technology in the mechanical manufacturing industry, the mold manufacturing industry will enhance its ability to integrate new technologies and integrate software and hardware, promote the development of production manufacturing towards automation and intelligence, and thereby improve mold processing efficiency and manufacturing precision. Based on the existing level of technology and manufacturing capabilities, the mold manufacturing industry is gradually upgrading to efficient, automated, and intelligent production through the comprehensive integrated application of communication technology, big data, and Internet of Things technology, comprehensively enhancing product design capabilities and production process control capabilities.

Get the latest price? We will reply as soon as possible (within 12 hours)