What Things Are Cast? Detailed Explanation of the Most Complete Casting Process in History(Part3)

2024-02-15 08:00

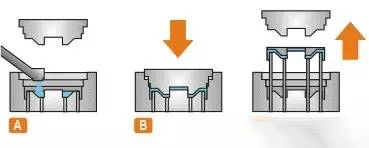

(8) Squeezing die casting

Squeeze casting: It is a method of solidifying and flow-forming liquid or semi-solid metal under high pressure to directly obtain parts or blanks. It has the advantages of high utilization rate of liquid metal, simplified process and stable quality. It is an energy-saving metal forming technology with potential application prospects.

Process flow:

Direct squeeze casting: spray coating, pour alloy, mold closing, pressurization, pressure maintaining, pressure relief, mold splitting, blank demoulding, reset;

Indirect squeeze casting: spray coating, mold clamping, feeding, mold filling, pressurization, pressure maintaining, pressure relief, mold splitting, blank demoulding, and reset.

Technical features:

1. It can eliminate internal defects such as pores, shrinkage cavities and shrinkage porosity;

2. Low surface roughness and high dimensional accuracy;

3. It can prevent the occurrence of casting cracks;

4. Facilitate mechanization and automation.

Application: Can be used to produce various types of alloys, such as aluminum alloys, zinc alloys, copper alloys, ductile iron, etc.

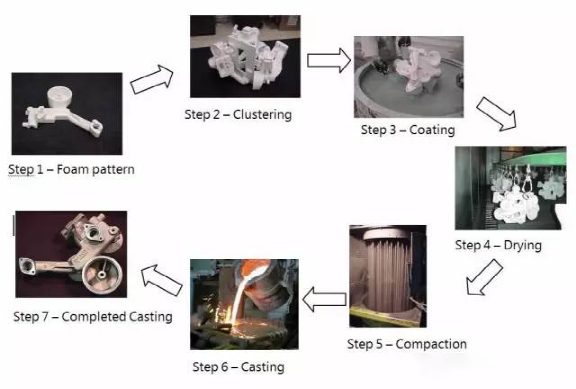

(9) Lost foam casting

Lost foam casting (also known as real mold casting): paraffin or foam models similar in size and shape to the casting are bonded and combined into model clusters. After being painted with refractory paint and dried, they are buried in dry quartz sand and vibrated to shape. It is a new casting method that vaporizes the model by pressing it down, and the liquid metal occupies the position of the model, and then solidifies and cools to form a casting.

Process flow: pre-foaming → foam molding → coating → drying → shaping → pouring → sand falling → cleaning

Technical features:

1. The casting has high precision and no sand core, which reduces the processing time;

2. No parting surface, flexible design and high degree of freedom;

3. Clean production, no pollution;

4. Reduce investment and production costs.

Application:

Suitable for producing precision castings of various sizes with complex structures, with no limit on alloy types and production batches. Such as gray cast iron engine box, high manganese steel elbow, etc.

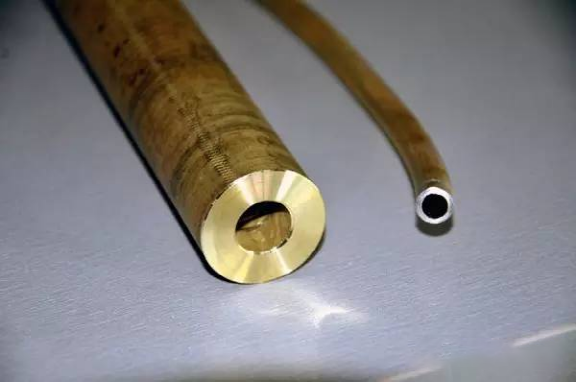

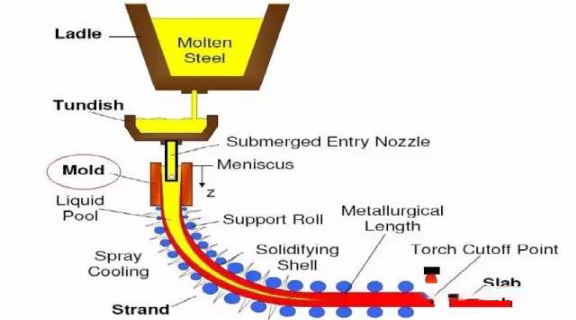

(10)Continuous casting

Continuous casting: It is an advanced casting method. Its principle is to continuously pour molten metal into a special metal mold called a crystallizer. The solidified (crusted) castings are continuously poured from the other side of the crystallizer. Pulled out at one end, it can obtain castings of any length or a specific length.

Process flow:

Technical features:

1. Because the metal is cooled rapidly, the crystallization is dense, the structure is uniform, and the mechanical properties are good;

2. Save metal and increase yield;

3. The process is simplified and modeling and other processes are eliminated, thereby reducing labor intensity; the required production area is also greatly reduced;

4. Continuous casting production is easy to implement mechanization and automation, and improves production efficiency.

Application:

Continuous casting method can be used to cast steel, iron, copper alloy, aluminum alloy, magnesium alloy and other long castings with constant cross-sectional shape, such as ingots, slabs, bar blanks, pipes, etc.

Get the latest price? We will reply as soon as possible (within 12 hours)